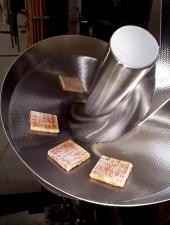

Food tends to stick to metal especially at cold temperatures, like Ralphie’s tongue on a flagpole. We make spiral chutes using rigidized stainless steel when handling frozen product to reduce friction, resist corrosion, and maintain hygienic qualities.

Food tends to stick to metal especially at cold temperatures, like Ralphie’s tongue on a flagpole. We make spiral chutes using rigidized stainless steel when handling frozen product to reduce friction, resist corrosion, and maintain hygienic qualities.

The features of rigidized stainless steel not only boost efficiency but also protect consumer health by reducing contamination hazards.

This material stands as a fundamental element for dependable and compliant food processing systems. For operations managing frozen products, selecting rigidized stainless steel spiral chutes is a prudent decision for sustained performance and safety.

In the food processing industry, especially when dealing with frozen products, selecting appropriate materials for equipment is essential to maintain safety, operational efficiency, and adherence to regulatory requirements. Rigidized stainless steel, a textured variant of stainless steel, is increasingly favored for conveyors and chutes that directly contact frozen foods. The primary reason for its utilization is its mitigation of challenges in low-temperature settings.

Rigidized stainless steel involves a specialized texturing process that imparts three-dimensional patterns to the metal surface, enhancing its mechanical characteristics. This material typically uses austenitic grades like 304 or 316 as the base, with textures that increase rigidity, reduce weight through down-gauging, and improve durability. The texturing minimizes surface contact area, which is particularly beneficial in applications requiring smooth material flow.

Frozen food operations frequently involve temperatures below -40°C (-40°F), where material brittleness can pose issues. Rigidized stainless steel performs well in these conditions, preserving ductility and toughness at cryogenic levels. The texturing further enhances performance by reducing friction and static cling, which helps prevent frozen products from sticking to the conveyor surface—a common problem due to moisture and ice formation. This minimizes jam-ups and downtime, ensuring consistent flow in spiral chutes, even when installed in freezing processing or package areas. In contrast to flat metals, the reduced contact area in rigidized steel lowers the coefficient of friction, particularly in wet or icy conditions, facilitating smoother handling of frozen goods.

Exposure to moisture, salts, and acidic food residues presents corrosion risks in food processing. Rigidized stainless steel provides superior resistance to pitting, crevice corrosion, and stress cracking, even in environments with high chloride content. Variants like 316 alloy offer heightened protection for applications involving frozen seafood. The texturing process bolsters overall durability, allowing for lighter gauges without sacrificing strength, which extends equipment life and lowers maintenance expenses. There is also minimal danger of contamination from degradation, as the material resists wear effectively.

Rigidized stainless steel contributes to efficient operations in frozen food facilities beyond its fundamental properties. Its biocompatibility and non-reactivity comply with overlapping medical and food safety protocols. The material's weldability and formability enable customized conveyor designs, such as modular setups for easy disassembly and cleaning. From an environmental perspective, stainless steel is fully recyclable, supporting sustainable practices. Moreover, the reduced friction enhances material throughput, making it ideal for high-volume frozen food lines.

And it doesn’t just work on tongues. Rigidized spiral chutes are ideal for handling frozen patties, waffles, potatoes, or even packaged meals.