News

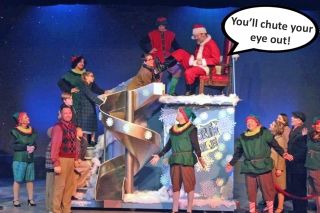

When it comes to handling precious cargo, Santa knows where to go. The crew at Stevenson Company’s workshop came up with a handy slide for the North Pole as featured in a production of “A Christmas Story the Musical” at Topeka Civic Theatre. In the classic production, grumpy Santa kicks little Ralphie down the slide at Higbee’s department store. The directors at America’s longest running dinner theater called on the Spiral Chute experts to come up with a slide design.

When it comes to handling precious cargo, Santa knows where to go. The crew at Stevenson Company’s workshop came up with a handy slide for the North Pole as featured in a production of “A Christmas Story the Musical” at Topeka Civic Theatre. In the classic production, grumpy Santa kicks little Ralphie down the slide at Higbee’s department store. The directors at America’s longest running dinner theater called on the Spiral Chute experts to come up with a slide design.

Stumpf (left) speaking with Hansen (middle) and Lyddane (right)Washburn Institute of Technology partners with industrial leaders to ensure students are well-prepared for the workforce. These experts assess curriculum, facilities, equipment and technology to keep Washburn Tech at the forefront of technical education.

Stumpf (left) speaking with Hansen (middle) and Lyddane (right)Washburn Institute of Technology partners with industrial leaders to ensure students are well-prepared for the workforce. These experts assess curriculum, facilities, equipment and technology to keep Washburn Tech at the forefront of technical education.

Though he was born in Pennsylvania, Dr. Samuel J. Crumbine made history in Kansas. Dr. Crumbine’s pioneering public health practices established food safety and sanitation practices in the United States. Crumbine did some medical training in Cincinnati before migrating to Kansas with his wife. Dr. Crumbine made a reputation for himself as the feisty doctor who strolled the streets of Dodge City in a Prince Albert coat and a holstered six-shooter.

Dr. Crumbine’s first contribution to public health improvement was at a small restaurant in Dodge City. Being a frequent diner, Dr. Crumbine convinced the management to serve milk in individual bottles instead of open jugs or pitchers. This served as a safer and more sanitary dispensing process.

The next big thing in innovation is coming to Topeka. Plug and Play, a globally recognized venture capital fund and corporate innovation platform, has picked Topeka as a location for their next accelerator program. As Plug and Play’s next startup accelerator city, Topeka will host upwards of 20 startup companies per year as each one goes through the 3-month startup accelerator program.

Can stainless steel get stained? Unfortunately, yes. Can you do anything about that? Fortunately, yes.

At our shop, the world revolves around stainless steel. We cut it, bend it, weld it, roll it, so we’ve had a lot of experience with stains, scratches, and finishes. If it can happen, it probably happened here at Stevenson. The team works exclusively for industrial applications, but on the personal side, we are also the go-to experts for Aunt Petunia who left the cast iron pan in the sink on Mother’s Day, or Cousin Eddie who scratched his work surface with a beer cooler. Here are some expert tips we share with them: